I am an accomplished engineer with over a decade of experience in the automotive manufacturing industry. Since 2013, I have been a part of Denso, the world's second-largest supplier of automotive parts and systems. My journey began as a mold design engineering co-op during my junior year at Western Michigan University. Upon graduating in 2014, I quickly immersed myself in the complexities of Siemens NX design software while leading multiple mold builds.

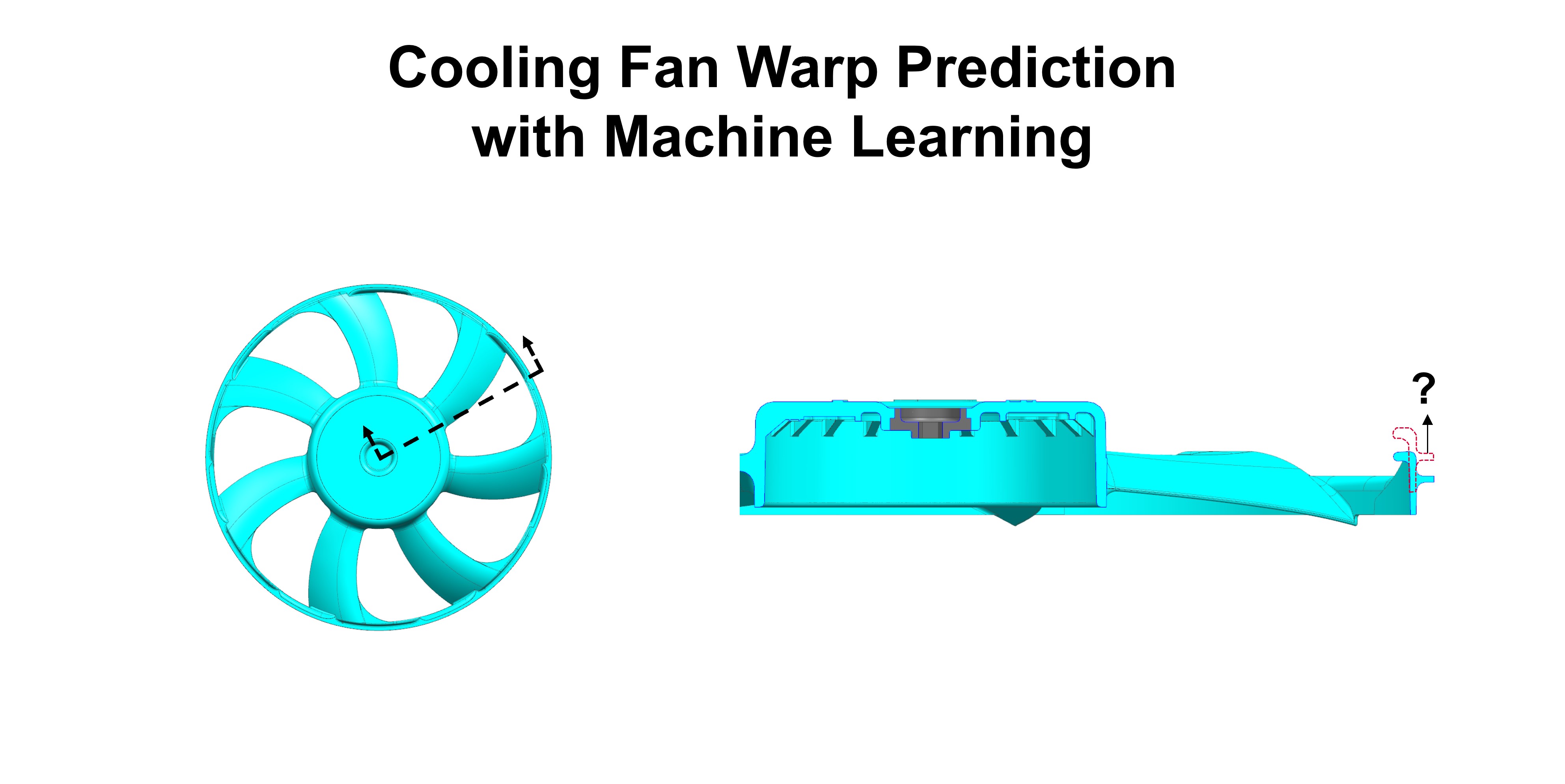

Throughout my career, I have designed, refined, and implemented customer-driven modifications across hundreds of molds. My expertise spans finite element analysis (FEA) using Moldex3D, overseeing new mold developments, and conducting mold trials to ensure optimal performance. Leveraging simulation techniques, I have optimized molding parameters such as runner designs and gate locations. Additionally, I have successfully integrated additive manufacturing by designing dozens of conformal cooled 3D-printed steel inserts, resulting in significant cost savings in mold maintenance and cycle time.

In recent years, I have expanded my expertise into data science, recognizing its transformative impact across industries. At Denso, I compiled and analyzed 20 years’ worth of cooling fan warp data to identify how product design features influence warping behavior. Using predictive modeling, I have successfully forecasted warp characteristics in new cooling fans, minimizing tuning costs and driving substantial savings.

My passion lies in problem-solving and optimization. I thrive on tackling complex challenges, applying creativity, and developing innovative solutions that enhance efficiency and performance.

"We cannot solve our problems with the same thinking we used to create them." - Albert Einstein